Introduction

N08904 also named Grade 904L stainless steel alloy,which contains high amounts of expensive ingredients, such as molybdenum and nickel, this high alloy stainless steel is added with copper to improve its resistance to strong reducing acids, such as sulphuric acid. While it is replaced by lower cost SS31803/SS2205 stainless steel.Generally, no heat treatment is required after welding. If necessary, it should be heated to 1100-1150℃ and then cooled rapidly.

Chemical components (%)

Composition | C | Si | Mn | P | S | Cr | Ni | Mo | Cu |

Min | \ | \ | \ | \ | \ | 19.0 | 23.0 | 4.0 | 1.0 |

Max | 0.02 | 1.0 | 2.0 | 0.045 | 0.035 | 23.0 | 28.0 | 5.0 | 2.0 |

Mechanical properties

Rigidity | Tensile strength | Yield strength | Elongation |

≤200HB | ≥520MPa | ≥215MPa | ≥35% |

Physical properties

Density | Melting points | Specific heat | Magnetism | Resistivity | Thermal conductivity | Linear expansivity |

8.0g/cm3 | 1350-1400℃ | 455J/(Kg.℃) | \ | 0.85×10-6Ω·m(20℃) | 13.0W/(m.k)(100℃) | 15.0×10-6/K(0-100℃) |

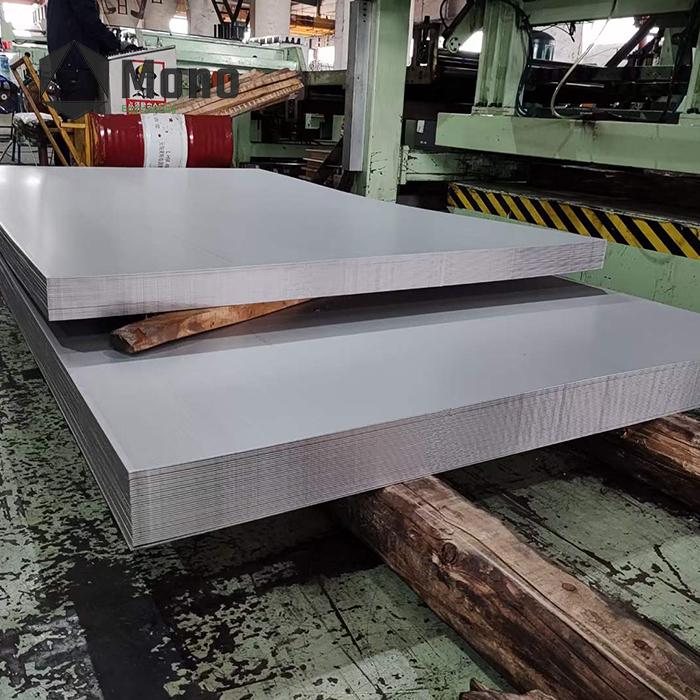

Available products

ASTM A479 hot and cold finished bars of stainless steel, including rounds, squares, and hexagons, and hot-rolled or extruded shapes such as angles, tees, and channels for use in boiler and pressure vessel construction.

ASTM A276 This specification covers hot-finished or cold finished bars except bars for reforging.It includes rounds,squares, and hexagons, and hot-rolled or extruded shapes, such as angles, tees, and channels in the more commonly used types of steels. The free-machining types(Note2) for stainless general corrosion resistance and high-temperature service are covered in a separate specification.

ASTM B240 This specification for stainless steel plate,sheet,and strip for pressure vessels and for general applications.

Advantages

(1) Processing performance: The processing performance of N08904 is similar to that of other austenitic stainless steels. There is a tendency for tool sticking and work hardening during processing. It is recommended to use carbide tools with positive rake angles and use appropriate cutting coolants.

(2) Corrosion resistance: N08904 can be passivated even in reducing environments such as sulfuric acid and formic acid, showing an extremely low corrosion rate. It has good resistance to crevice corrosion in chloride solutions and is insensitive to stress corrosion in chloride-rich environments.

(3) Welding performance: N08904 can be welded by a variety of welding methods, including manual arc welding or gas shielded welding. When welding, it is advisable to use a small line energy, continuous and fast welding rate.

Applications

(1) Petroleum and petrochemical equipment, such as reactors

(2) Sulfuric acid storage and transportation equipment, such as heat exchangers.

(3) Flue gas desulfurization equipment in power plants, the main use parts are: tower body, flue, baffle plate, internal parts, spray system

(4) Scrubbers and fans in organic acid treatment systems.

(5) Seawater treatment equipment, seawater heat exchangers, papermaking industry equipment, sulfuric acid and nitric acid equipment, acid making, pharmaceutical industry and other chemical equipment, pressure vessels, food equipment

(6) Pharmaceutical factories; centrifuges, reactors, etc.

(7) Plant foods: soy sauce tanks, cooking wine, salt tanks, equipment and dressings.

MONO Group is one of Austenitic stainless steel, Duplex stainless steel and Precipitation-hardened stainless steel etc manufacturer&Supplier&Wholesaler from China,We can supply ASTM /DIN/ISO/GB stndard high quality alloy plate,sheet,round bar,tube.pipes,fittings,flange,pls contact us freely for your RFQ to info@monokj.com